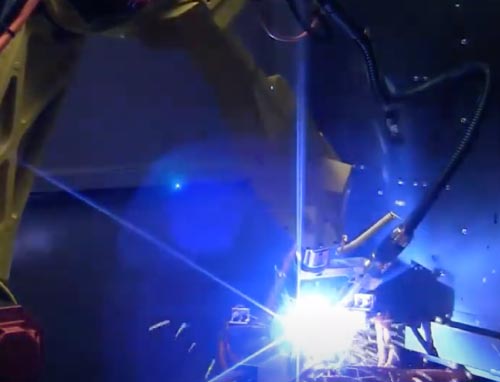

ROBOT WELDING

Description:

The usage of CNC machinery for high precision welding projects.

Key Feature:

The use of Robotic welding ensures consistency and high quality for repetitive parts. Eliminating variation and possible defective parts.

Info:

Consider Robotic welding for your next High Volume Project

The robotic welding process consists of an automated welding procedure that focuses on ensuring accuracy, enhancing safety protocols, as well as eliminating excess time expenditure.

FAQs

Robotic welding offers significant advantages over manual arc welding. While skilled welders can achieve precision, robotic welding provides for more consistent precision and accuracy throughout the day. Robotic welding cells can operate around the clock, increasing efficiency and productivity.

Robotic welding systems are best suited for High-volume, low-variety applications where parts are repetitive.

Bepicon can provide robotic welding for Carbon Mild Steel as well as Stainless Steel.

| Device Specifications

FANUC Robot ARC Mate 100iC

Precision 6-Axis C02 Welder. Reach - 1098mm

REQUEST A QUOTE

| machine in action

The device is better suited for high-volume

welding of products with the same

design specifications.

| our services

Our team offers a complete fabrication solution, through a variety of manufacturing processes and machinery.

The cutting of materials, up to 70mm in thickness, including bevel cutting capabilities.

The manufacturing of certified products specifically utilised within the telecommunications industry.